Snowy Hydro today announced the outcomes of its major projects resets, for Snowy 2.0 and the Hunter Power Project.

Snowy 2.0

- Revised total cost to complete is $12 billion. At the end of June 2023, expenditure on the project was $4.3 billion, with 80% of these funds reinvested in the Australian economy.

- First power to be delivered in the second half of 2027 and a target date for commercial operation of all units of December 2028.

- The fixed-price EPC Contract was executed by Snowy Hydro and Future Generation Joint Venture (FGJV) following Final Investment Decision in a relatively benign and supportive environment. The EPC Contract is no longer fit for purpose.

- Snowy Hydro and FGJV are finalising an amendment to the existing EPC Contract to move to an incentivised target cost contract model. Snowy Hydro will also settle all outstanding claims with FGJV.

- Delivery of an additional 200 MW or 10% capacity; bringing total capacity to 2,200 MW.

- Snowy 2.0 is the largest renewable energy project under construction in Australia and will provide crucial deep storage central to Australia’s renewable transition.

- The value of Snowy 2.0 to the national electricity market has increased materially since the Final Investment Decision in December 2018.

- Snowy 2.0 will provide 350,000 MWh of energy storage for 150 years.

- Snowy 2.0 remains value accretive, with the Company currently projecting a NPV of approximately $3 billion (based on a $12 billion revised target total cost and December 2028 delivery).

- Snowy Hydro is working closely with its Shareholder to develop an appropriate capital structure for the Company to support the increase in costs and to maintain the Company’s target credit rating of BBB+.

HPP

- The total target cost is now $950 million and will be funded by Snowy Hydro.

- The project delivery remains December 2024.

- The project remains economically viable on a forward looking basis with the value of its firming capacity clearly demonstrated in the May/June 2022 energy crisis.

Snowy Hydro CEO Dennis Barnes said the project resets will enable the commercially sustainable and successful delivery of both projects.

“I am committed to ensuring these critically important projects are transparent and are placed on a robust and sustainable footing. Moving to an incentivised target model with FGJV will result in closer collaboration, stronger oversight and alignment of interests between Snowy Hydro and FGJV. ” Mr Barnes said.

“Snowy 2.0 is being engineered to deliver clean and reliable storage and electricity generation for Australians for the next 150 years. It is a truly transformative national project that is generating jobs and significant investment in regional areas; it will deliver benefits immediately following its completion and will continue to do so for many future generations of Australians.

“Snowy 2.0 involves billions of dollars of investment, with approximately 80% going into Australian jobs, goods, services and skills. We are building the skills of local workers that can later be used elsewhere to assist in Australia’s ongoing energy transition.”

“The Hunter Power Project is an important project in Australia’s energy transition, enabling the roll-out of wind and solar projects by firming these intermittent generation sources into reliable power,” Mr Barnes concluded.

Fact sheet

Webuild Clough media statement

Background Information

Snowy Hydro today detailed the outcome of the review and reset process for key electricity projects, Snowy 2.0 and the Hunter Power Project.

Snowy 2.0

The estimated total cost for Snowy 2.0 project delivery has been revised to $12 billion, with expenditure on the project to date of $4.3 billion. The terms of the contract with Future Generation Joint Venture (FGJV) are being finalised to move to an Incentivised Target Cost contract model, which will result in closer collaboration, stronger oversight and alignment of interests between Snowy Hydro and FGJV. Snowy will also settle all outstanding claims with FGJV.

The target date for commercial operation of all units is December 2028 with first power to be delivered in the second half of 2027.

Through the project reset process Snowy Hydro has worked with FGJV and hydro technology contractor Voith Hydro to increase the capacity of the power station by 10%. Snowy 2.0 will now deliver dispatchable generation capacity of 2,200 MW, as well as providing energy storage of 350,000 MWh (or 160 hours of generation at maximum output).

The cost revision reflects the compound effect of extraordinary factors. The external factors have impacted major projects around Australia and globally, in particular:

- The major disruption caused by the Covid-19 pandemic;

- Delayed ability to mobilise, given critical shortages of skilled labour, exacerbated by quarantine and movement restrictions;

- Extended and ongoing disruption to global shipping and supply chains caused by the pandemic, conflict and natural disasters, delaying access to key materials;

- Significant inflation in costs of key construction materials and inputs; and

- Significant inflation in labour costs.

In addition to the external factors, the project has been impacted by:

- Design immaturity at final investment decision, with a number of design elements requiring more time to complete due to their technically complex nature. The final design now being more expensive to construct; and

- The impact of variable site and geological conditions, with the most impactful being the soft ground encountered that is delaying tunnel boring machine (TBM) Florence’s progress at Tantangara.

Despite the challenges outlined above, the project remains economic. Strong and growing market demand for dispatchable electricity is expected to underpin demand for the services provided by the project well into the future.

Construction of Snowy 2.0 is now approximately 40% complete and solid progress continues to be made, including:

- Excavation of the main access and emergency cable and ventilation tunnels is now complete – approximately 6km of tunnelling;

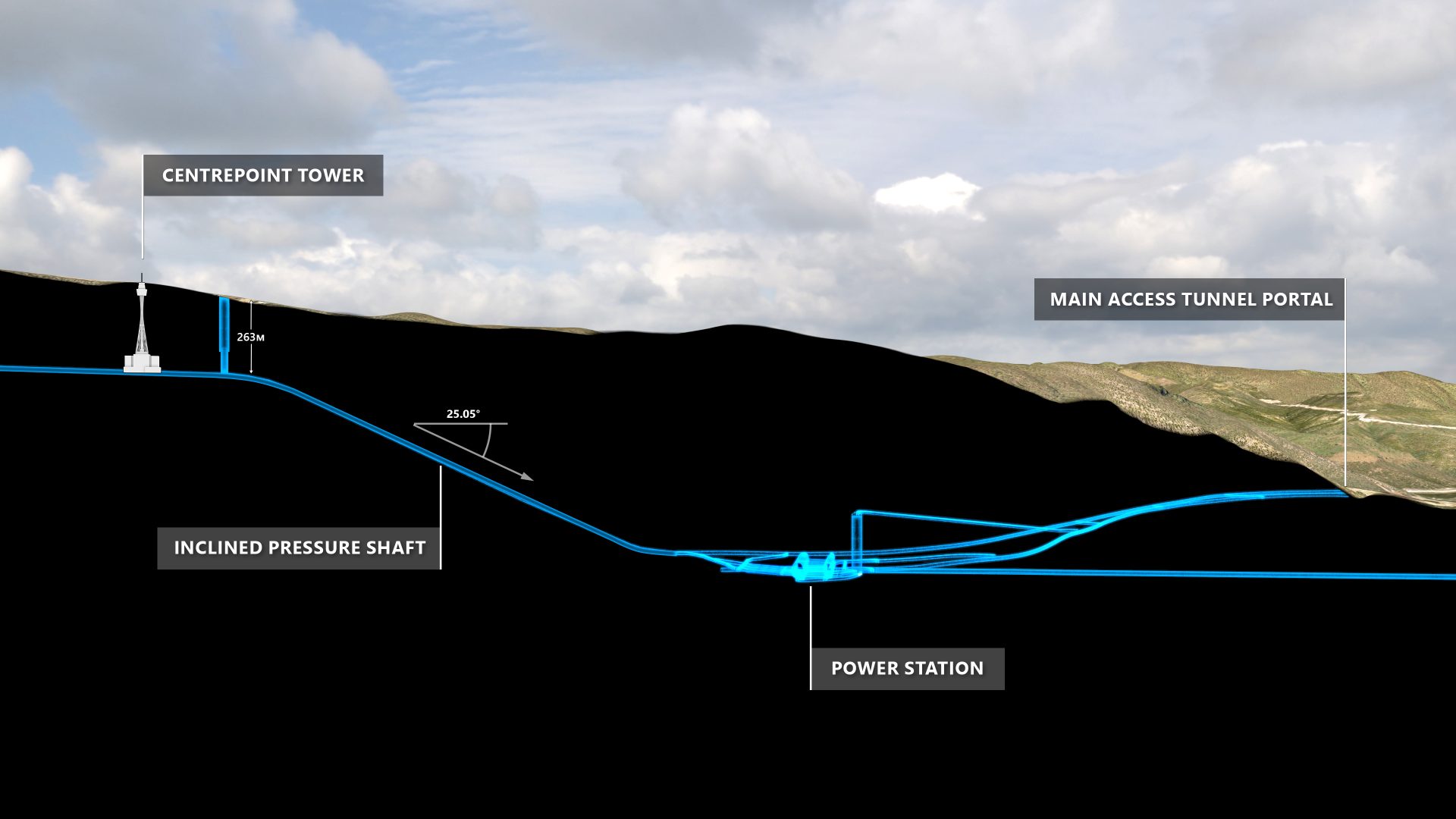

- Excavation on the 6km tailrace tunnel has commenced and tunnelling on the 1.45km inclined pressure shaft will commence shortly;

- Work on the underground power station is now underway with access available from both ends and excavation and support of cavern crowns underway;

- Excavation at the Talbingo intake (where water will enter during pumping and exit during generation) is halfway complete, with 310,000m3 of earth excavated, while the first stage of earthworks at the Tantangara intake are complete, involving the movement of 205,000m3 of earth; and

- Manufacturing of the six pump turbines has commenced, the first major mechanical component has been shipped and has been transported to site.

Meanwhile, excavation of the headrace tunnel by TBM Florence is now ready to be continued, subject to the receipt of necessary regulatory approvals.

The project currently has a team of approximately 2,700 Australians dedicated to its safe and efficient delivery. An additional 1,500 jobs are forecast over the project’s lifespan.

Hunter Power Project

The Hunter Power Project has experienced similar challenges to Snowy 2.0 and following a comprehensive review the expected cost is now $950 million. Despite the increased cost the Hunter Power Project remains economic.

Construction continues to progress on schedule, with about 460 people working on the project, which remains on track to be delivered by December 2024.