In the June update of the pumped-hydro expansion of the mighty Snowy Scheme, Snowy 2.0’s Alex Woschitzka explains construction progress at the massive Talbingo and Tantangara intakes. The project’s Quality Coordinator also checks in on the transformation of a narrow fire trail through steep terrain into a road suitable for heavy vehicles.

Significant progress has been made at the Talbingo intake, where water will exit the tailrace tunnel when Snowy 2.0 generates power. This is also where water enters the tunnel for pumping.

Construction teams have moved more than 310,000 cubic metres of earth to date, about half the total amount that will need to be moved. More than 24,000 metres of rock bolts have been installed and 8,300 square metres of shotcrete sprayed to support the wall.

As part of quality assurance, the shotcrete must be tested for compressive strength. Samples are taken from the truck and also cored from the face to ensure it meets the intended strength requirements. For the rock bolts, pull-testing is conducted to ensure they have been correctly installed, and meet the design and quality requirements.

When completed, the total height of the Talbino intake excavation will be 104 metres, with about 31 metres of that below the water level. The concrete intake structure will be an impressive 50 metres in height.

Construction is well underway on an internal access road through mountainous terrain. With the help of Snowy 2.0 subcontractor Leed, a narrow fire trail will be widened into a six-kilometre road to enable heavy vehicles to access a rock emplacement area on Talbingo Reservoir.

Works began from both ends across very challenging terrain, achieving a major milestone recently when the two pioneering fronts joined across the Middle Creek cliffs. A temporary bridge with a 36-metre span has been installed across Middle Creek and is capable of supporting a fully-loaded 80-tonne dump truck.

In another milestone achieved in June, stage one earthworks have now been completed at the Tantangara intake. The first stage involved excavation of about 205,000 cubic metres of earth with a further 78,000 cubic metres of drilling and blasting earthworks expected in the next stage.

To support the excavation, more than 18,000 metres of rock bolts have been drilled and installed, and approximately 6,100 square metres of shotcrete sprayed. The excavation is currently about 26 metres deep and will be extended to a total depth of 55 metres.

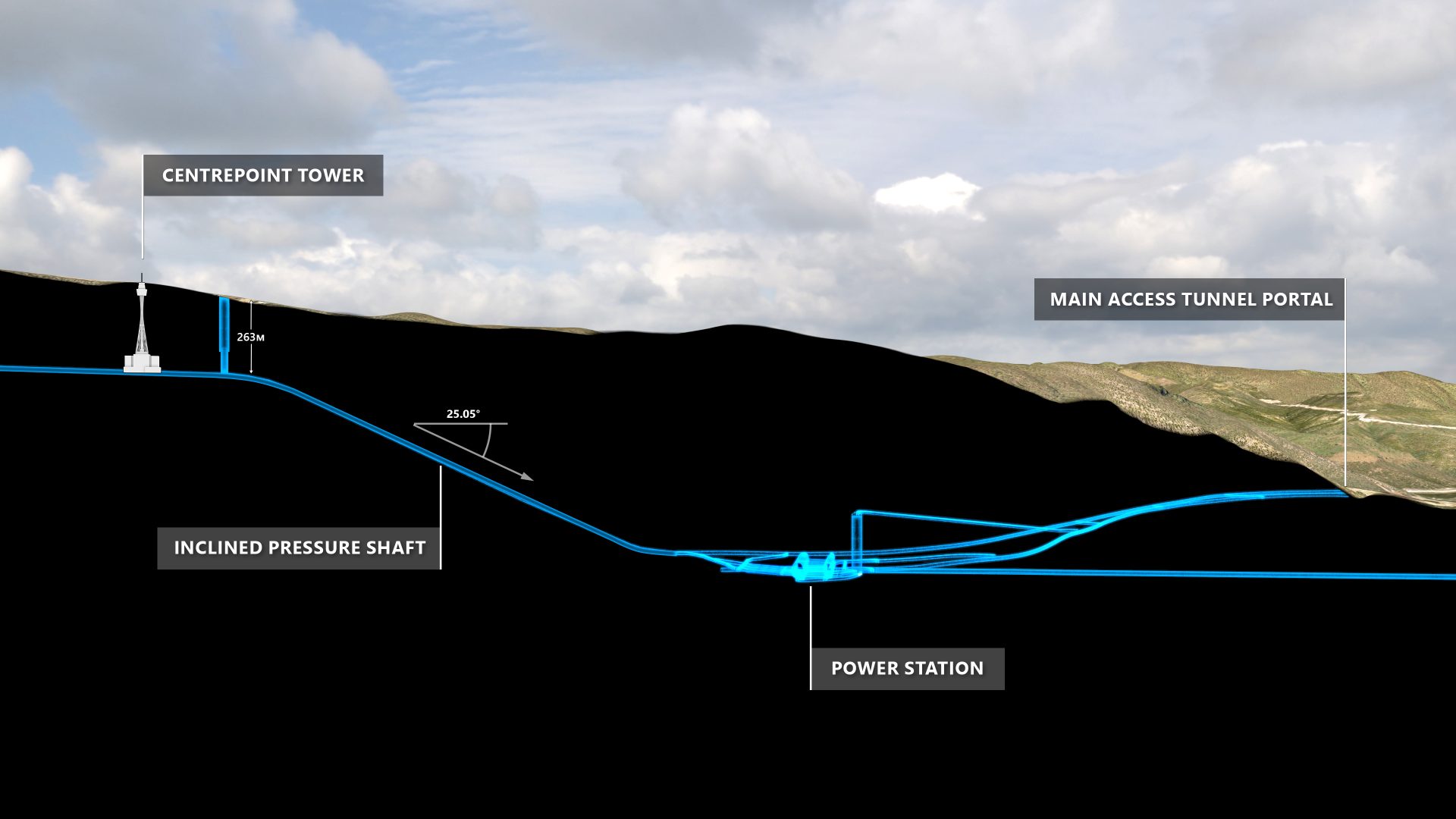

Tantangara intake is where water will enter the headrace tunnel when the Snowy 2.0 power station is in generation mode. When in pumping mode, water will exit through the intake and fill Tantangara Reservoir.